JUMBO – 90 (BIO-MASS BRIQUETTING PLANT)

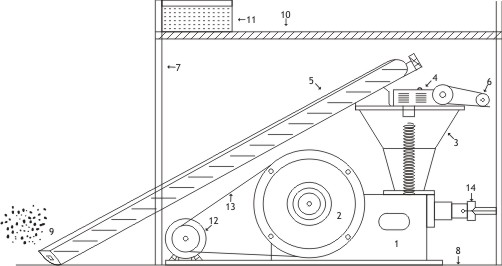

JUMBO – 90 SIDE ELEVATION WITH SIDE CONVEYER

- Briquetting Press

- Load Wheel

- Kupy

- Reduction Gear

- Screw Conveyor

- Electric Motor

- Bricks Wall of Shade

- Ground Flooring

- Space for Raw Material

- Open Terrace

- Water Tank

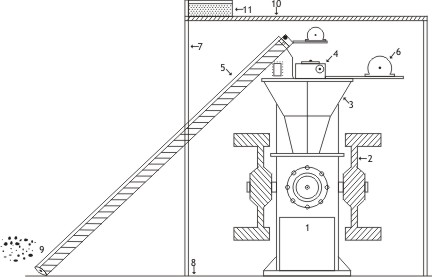

JUMBO – 90 FRONT ELEVATION WITH BACKSIDE CONVEYER

- Briquetting Press

- Load Wheel

- Kupy

- Reduction Gear

- Screw Conveyor

- Electric Motor

- Bricks Wall of Shade

- Ground Flooring

- Space for Raw Material

- Open Terrace

- Water Tank

- Main Electric Motor

- Flat Belt

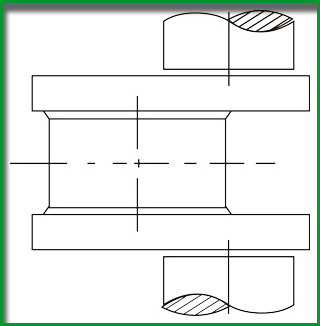

- Die Holder

PARTS & COMPONENTS OF JUMBO – 90

Die Holder

Split die

Tapper Die

Ram

Feeder Box

Waram

Ram Holder & Oil Seal

Piston

Collat

OUR LATEST IDEAL PLANT

Our new plant JUMBO-90 press produce 90. mm dia. Briquettes. It produces at the ratio of 1500kg / Hrs. It produce Briquettes directly from 20-25 mm size of raw material residuals.

TECHNICAL DETAILS FOR “JUMBO-90″

| Model | “JUMBO – 90″ |

| Type | Crank Type |

| Stock | 200 mm |

| R. P. M. | 230 |

| Total Power Requirement | 91 HP. |

| Production Capacity (+ 20% Depending on Density and Quality of Raw Material) | 1000-1500 Kg/Hr. |

| Finished Products Size | 90 mm Dia |

| Finished Product Shape | Cylindrical |

| Finished Product Length | 6″ to 12″ |

| Raw Material Form | Up to 25mm Size can be Used Directly |

ADVANTAGES OF JUMBO-90

- Power consumption

- Maximum production capacity

- Low maintenance cost

- All type of raw material suitable for JUMBO-90 also sugarcane bagasse is also suitable

- Easy in handling Briquettes due to large size of briquettes

- Ideal for boiler operator & firemen

USE OF BRIQUETTES

The white coal is ideal fuel which substitutes coal, fire-wood, lignite and other conventional fuels for heating steam generation.

The demand of white coal emerges from shortage of conventional fuels like coal, fire-wood arising day by day. So it indicates golden future for white coal and really it is ideal future Fuel.

WHITE COAL CAN BE USED BY INDUSTRIAL UNIT VIZ.

- Paper Mills

- Solvent Extraction

- Vegetable Planst

- Textile Units

- Chemical Plants

- Dyeing Houses

- Food processing units

- Hotels

- Milk Plants

- Spinning Mills

- Leather industries

- Laminating industries

- Bricks Making & Lot Others

PROJECT HIGHLIGHT

- High Profitability on investment

- Excellent Growth Potentiality

- Ready Market

- Short Gestation and Quick Payback

- Employment Potentiality

- Wide variety, easy availability of raw materials

- Conversion of natural resources (wastage) in hi-tech energy & maintenance of ecological balance

- Minimum working capital

ADVANTAGES OF THIS FORM OF FUEL ARE AS UNDER

- Consistent Quality

- Economic to users compared to other forms.

- High calorific value ranges between 3500 – 5000k. Cal./kg.

- No pollution since it does not emit any sulphur of phosphorous fumes & there is on need for expensive pollution control equipment.

- Easy in handling and storage due to its size.

- Moisture % is very less 2-5% compare to lignite & fire wood & coal where it is 25-30 %