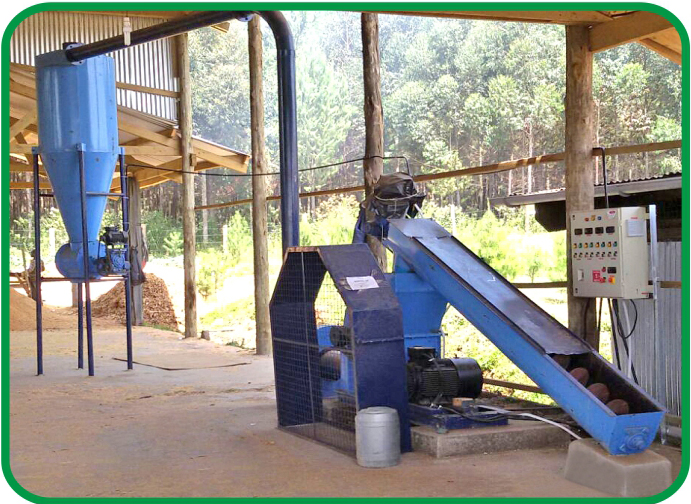

Wood Hammer Mill

Wood Hammer Mill is blessed with numerous benefits contrasted with other sorts of smashers, for example, huge decrease rate, high creation limit, even squashed impacts, low energy utilization, and basic construction, and so on It very well may be utilized to pound hard delicate and feebly destructive materials. After pounding, crude materials are uniform and with appropriate dampness content to meet further preparation.

Wood hammer mill is mainstream with numerous enterprises and we suggest it too on the off chance that you are thinking about biomass industry speculation. Biomass fuel takes wood chips, wood sawdust, nut stalks, and corn straws, etc as materials and wood hammer mill can pulverize these materials into 3mm-5mm wood materials for Biomass Briquettes or Pellet use.

It is the affecting impact that makes hammer plant pulverize materials. Wood materials are affected by high-velocity rotational sleds when they enter the mallet plant. The wrecked materials hit over and over with the pivoting hammers. There are spaces where squashed materials are crushed out. In light of the sensible plan and great materials, the wood hammer factory works steadily.

RAW MATERIAL OF HAMMER MILL

- All kind of Wood Piece

- Straw, Grass

- Stalk

- Tree Branches

- Waste Cardboard

- Bamboo

- Corn Stalk

- Peanut Shell

- Wheat Stalk

- Cotton Stalk

- Biomass Shell

| TECHNICAL SPECIFICATION OF MACHINE | |||

|---|---|---|---|

| Production Capacity | 1000 To 1250Kgs. Per Hr. | ||

| Size of Particles | Dust (Less Than 10mm) | ||

| Power Requirement 40 HP | Hammer Motor | 25 HP | |

| Blower Motor | 10 HP | ||

| Conveyor Motor | 2 HP | ||

| Air Valve Motor | 2 HP | ||

| Screw Conveyor 10 Feet | Material Handling with Gear Box Bend Cyclone | ||

| Foundation Stand | Pulley and Belt Blower with Pipe | ||