- Have any questions?

- +91 87584 77377

- +91 96876 15656

- info@ronakeng.com

Raw Materials for Briquettes

Biomass Briquettes

August 11, 2022

Uses of Biomass Briquettes

August 16, 2022Raw Materials for Briquettes

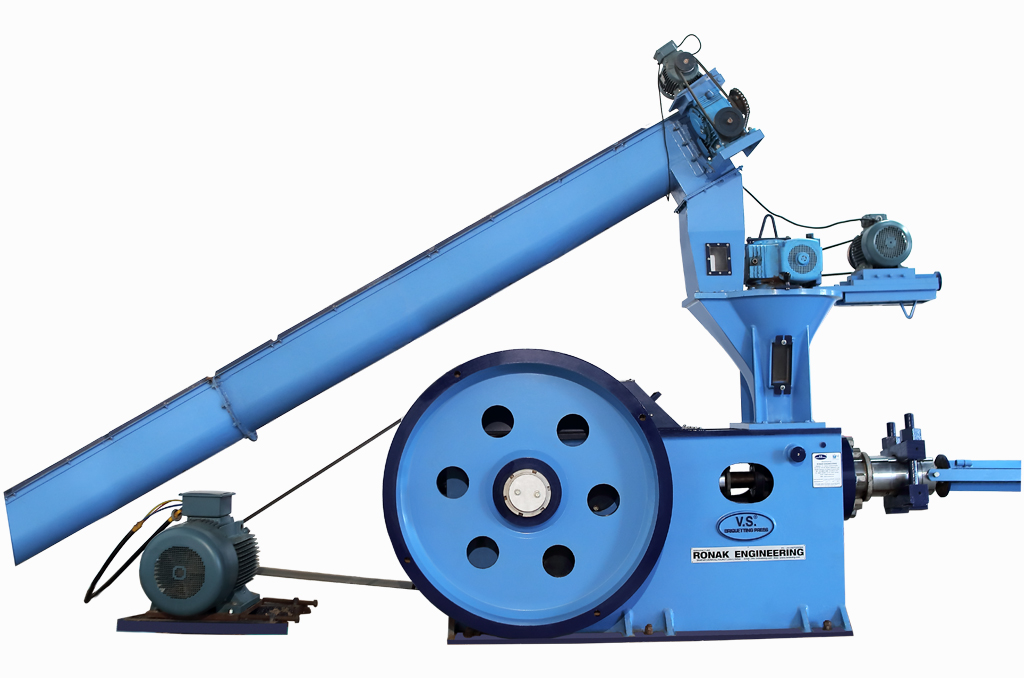

There are two kinds of raw substances for biomass briquettes. One is field lives and the other is the cycle waste. Most deposits are scorched right now of social events and in this manner a high anticipated normal substance for biomass briquette. The volume of buildups made per unit of improvement is an extensive range, contingent solidly upon the reap, the force of cultivation, and the climate.

Generally speaking, field deposits are huge, baled wheat straw has been put at around 100 kg/m3 and stacked cotton buildups at 55 kg/m3. Regardless, when chipped, cotton buildups simply have a mass thickness of 130 kg/m3. Then again, stacked wood has a mass thickness of north of 500 kg/m3. This suggests that the vehicle of deposits to a briquetting plant can end up being continuously expensive as the division from the site of the buildups to the plant increases. Moreover, most field deposits appear only for a given period in the year requiring intermittent vehicle cutoff points and limit limits. Getting back to the recently referenced model calculation: there would be the need to deliver practically 440 tons of regular substance in two or three days and, expecting baled straw wheat, an additional room of 4400 m3, which could be a construction with a system of 30 x 30 meters and 5 meters of height.

Another grouping is taking care of waste. all stores got from the treatment of a yield or wood are consolidated, for instance, espresso husks, groundnut shells, rice husks, coir dust, sawdust, furniture waste, and so on. On a fundamental level, the briquetting framework works splendidly for a wide extent of feedstock given they are homogeneous and contain clamminess under 15 %.

Read more Biomass Briquettes