About Us

We Manufacture Briquetting Plants, contributing to nature preservation with eco-friendly outputs

Since its founding in 2003, Ronak Engineering has become the leading Manufacture & Exporter of briquetting machines in India. The company exports its products to various countries in the world.

Advanced technology and processing have improved the quality of briquetting press. These include innovation in briquette preparation.

Advanced technology and processing have improved the quality of briquetting press

Our

Purchase

Excellence in Innovation, Durability, and Support

Don't Overlook

What Sets Us Apart ?

Automatic System

Our automatic and semi-automatic machines feature a siren system for efficient operation.

High-Quality Piston

We use hardened, high-quality pistons for enhanced durability and performance.

Cuppy Waram

Our reverse forward system minimizes machine damage, ensuring longevity.

Panel Control

Centralized panel controls enable easy machine operation by a single person.

Crank Shaft

We manufacture cranks with 6-pillars, chrome hardening, tempering, and grinding for superior strength.

Latest Technology

Constant innovation and timely upgrades keep our technology state-of-the-art.

Spare Parts

We produce high-quality spare parts for better maintenance and long-term durability.

Direct Connection with Customers

Direct sales ensure our products are available at reasonable and flexible prices.

Service Engineer

Service engineers in every Indian state and abroad ensure excellent service and maintenance.

Experienced Team

Our experienced team excels in machine manufacturing and provides regular training.

Service Support

One phone call away, we resolve machine issues within 48-72 hours.

Operator Training

We offer comprehensive training to operators on-site, covering machine operation and maintenance.

Live Plant Visit

Live plant visits provide insights into our machines and their technology.

Buyer and Supplier Support

We support briquettes and white coal buyers across India.

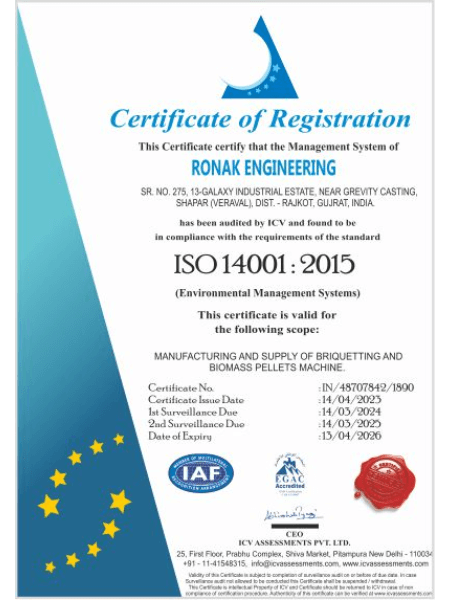

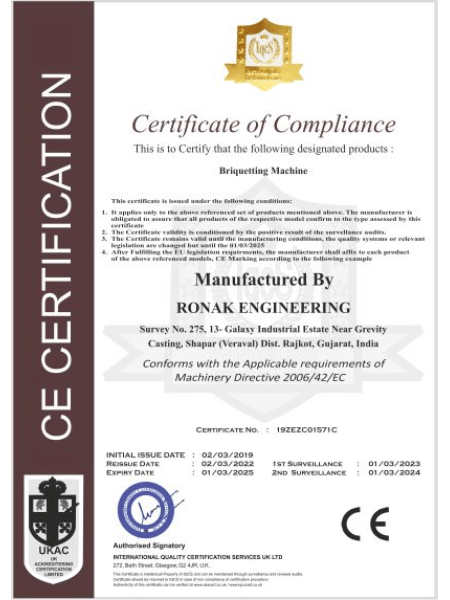

Certified Company

Ronak Engineering is an ISO 9000 and CE certified company, ensuring top-quality standards.

Our Motto

Is To Earn The Confidence & Trust Of Our Clients Rest Is Secondary