Our Product

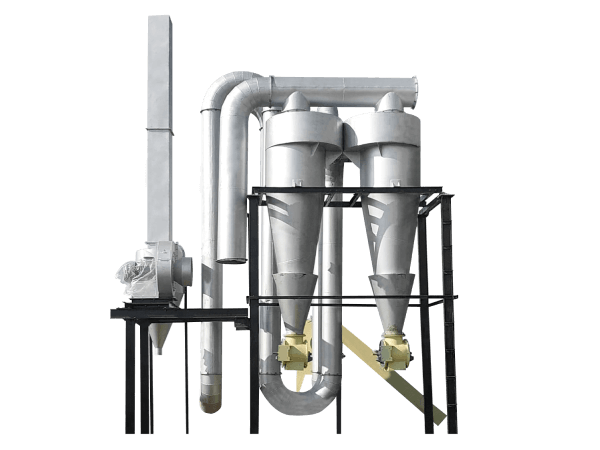

Sawdust Flash Dryer Machine

The sawdust flash dryer is new type design of biomass material drying equipment widely used in Wood Briquette Plant factory. Known as pipe dryer, it is good choice for solid raw material which has good flow ability. The suitable biomass material moisture content for making Wood Briquette and Biomass Briquettes is 8%-17%. This efficient wood dryer can process material with initial moisture content below 50%.

Sawdust Flash Air Agriculture Waste Dryer Manufacturer Exporter Supplier

Sawdust Flash Dryer Structure and Working Principle

The whole wood drying machine mainly consists of hot wind stove, material feeder, drying pipe, dying cyclone, cyclone separator and controlling system. When the sawdust pass through the pipeline, the wet moisture will be removed from the material and the dried sawdust is discharged from the cyclone separator. This drying machine adopts two time circulate heating system, strengthening the heat and mass transfer rate, material moisture at 50% can be dried into the requirement of making wood briquettes at one time, greatly save the labor. We have two types of sawdust dryer for the customers choose.

Advantages of Pipeline Drying Machine

- Adopt the hot air jet self-priming device, automatic feeding.

- Fast heat flow velocity, material is fully mixed, excellent drying effect

- Large intensity of drying, short drying time

- Big capacity, high thermal efficiency, energy-efficient and labour saving

- Simple structure, small occupation area, easy to install and repair

Technical Specifications

| Production Input Capacity | 1400 - 1600 Kgs. Per / Hr. (Upto 10mm) |

| Production Output Capacity | 800 to 1000 Kgs. Per / Hr. (Depend On Moisture Content) |

| Total Power Requirement | 39 HP Consumption |