- Have any questions?

- +91 87584 77377

- +91 96876 15656

- info@ronakeng.com

The Process to Make Biomass Briquettes

What are the Benefits of Paper Briquettes?

January 31, 2023

The Process to Make Wood Briquettes

February 4, 2023The Process to Make Biomass Briquettes

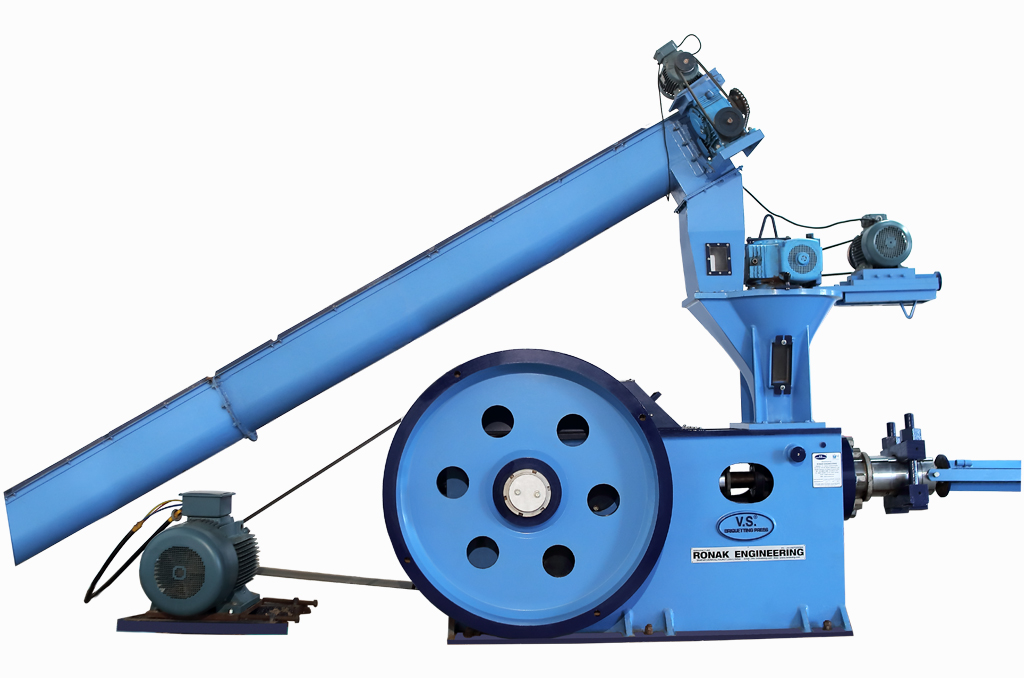

Biomass briquettes, for the most part, made of green waste and other natural materials, are normally used for power age, power, and cooking fuel. These pressed combinations contain different natural materials, including rice husk, bagasse, ground nutshells, common solid waste, and cultivating waste. The piece of the briquettes changes by area as a result of the openness of crude parts. The raw parts are gathered and stuffed into a briquette to consume longer and make transportation of the items less difficult. These briquettes are very surprising from charcoal since they don’t have huge groupings of carbonaceous substances and added materials. Diverged from petrol subsidiaries, the briquettes produce low net hard and fast ozone-harming substance radiations considering the way that the materials used are currently a piece of the carbon cycle.

One of the most generally perceived elements of the biomass briquette creation process is the means by which the biomass is dried out. Makers can use torrefaction, carbonization, or moving degrees of pyrolysis. Investigators assumed that torrefaction and carbonization are the most useful kinds of drying out biomass, yet the use of the briquette sorts out which strategy should be used.

Compaction is another component affecting creation. A couple of materials consume even more capably at whatever point compacted at low strains, for instance, corn stover grind. Various materials, for instance, wheat and grain straw require high proportions of strain to make heat. There are similarly extraordinary press developments that can be used. A chamber press is used to major areas of strength to make for a wide show of purposes. Screw removal is used to limit biomass into free, homogeneous briquettes that are filled in for coal in cofiring. This development makes a toroidal, or doughnut-like, briquette. The opening in the point of convergence of the briquette thinks about a greater surface district, making a higher consumption rate.

Read more about What are the Benefits of Paper Briquettes?