Transform your biomass production with Ronak Engineering’s Horizontal Die Pellet Machines. Our high-efficiency, durable machines convert various biomass materials into high-quality pellets. Achieve up to 1500 Kg/hr production capacity with our state-of-the-art technology. Contact us now to enhance your production efficiency and sustainability.

Horizontal Die Pellet Machine Manufacturer | Ronak Engineering

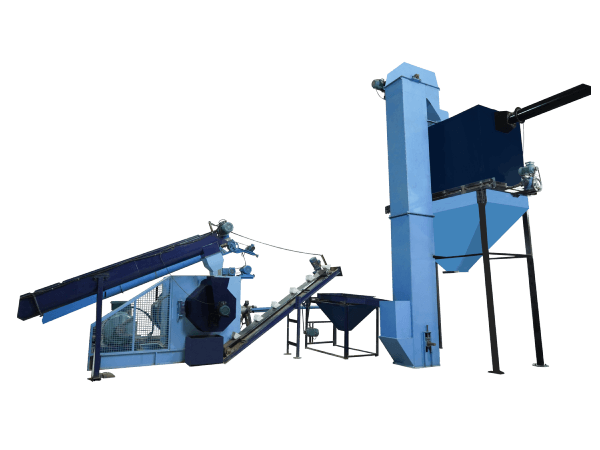

Ronak Engineering is a leading Horizontal Die Pellet Machine manufacturer and supplier. Our machines are designed to transform various biomass materials into high-quality pellets. The process is efficient, ensuring the best output for your production needs.

The Power of Pellet Mills

A pellet mill plant is more than just machinery. It is a comprehensive system designed to produce biomass pellets from various raw materials. These materials include sawdust, wood chips, agricultural residues, and other biomass feedstocks. Our plant systems are built to maximize efficiency and output.

Key Components of a Pellet Mill Plant

- Hammer Mill: This equipment grinds raw materials into smaller, manageable pieces. It ensures that the raw material is adequately prepared for the pelletizing process.

- Dryer: The dryer reduces the moisture content of the raw materials. This step is crucial for achieving the right pellet quality and durability.

- Pellet Mill: The core of the plant, the pellet mill compresses the prepared material into pellets. Our Horizontal Die Pellet Machine excels in this role.

- Cooler: After pelletizing, the cooler reduces the temperature of the pellets. This process makes the pellets suitable for storage and transportation.

Technical Specifications of Our Horizontal Die Pellet Machine

| Technical Specifications | Biomass Ring Die Pellets Mill 109 Hp |

|---|---|

| Feeding Raw Material Size | Less than 6mm |

| Moisture Content of Raw Material | Up-to 10% moisture content required |

| Production Capacity | 1200 to 1500 Kg/hr |

| Pellet Diameter | 8mm & 6mm (Cylindrical) |

| Pellet Length | 20mm to 50mm |

These specifications ensure that our machines meet the demands of high-volume production while maintaining quality.

Benefits of Using Our Horizontal Die Pellet Machine

- High Efficiency: Our machines are designed for high output, ensuring that you get more pellets per hour.

- Durability: Built with robust materials, our pellet mills are long-lasting and require minimal maintenance.

- Versatility: Suitable for various biomass materials, our pellet machines are adaptable to different production needs.

- Precision: The consistent size and quality of the pellets ensure better combustion and energy efficiency.

- Cost-Effective: Our machines are designed to reduce production costs, providing you with a better return on investment.

The Production Process: From Raw Material to Finished Pellets

The production process starts with raw material preparation. The hammer mill grinds the raw materials to the required size. Next, the dryer reduces the moisture content to optimal levels. The pellet mill then compresses the material into pellets. Finally, the cooler lowers the temperature of the pellets, making them ready for storage or transport.

Each step in the process is crucial for achieving high-quality pellets. Our machines ensure that each step is performed with precision and efficiency.

Why Choose Ronak Engineering?

Ronak Engineering stands out in the industry for several reasons:

- Expertise: With years of experience, we understand the intricacies of pellet machine manufacturing.

- Innovation: We continuously improve our machines to incorporate the latest technology and trends.

- Customer Support: Our team provides exceptional support to ensure your machinery operates smoothly.

- Customization: We offer tailored solutions to meet your specific production needs.

- Sustainability: Our machines contribute to sustainable energy solutions by efficiently converting biomass into pellets.

Applications of Biomass Pellets

Biomass pellets have a wide range of applications, including:

- Energy Production: Used as a fuel source for heating and power generation.

- Agriculture: Serves as animal bedding and feed.

- Industrial Use: Employed in various manufacturing processes as an energy source.

The versatility of biomass pellets makes them an essential component in various industries.

Conclusion

Ronak Engineering’s Horizontal Die Pellet Machines are the perfect solution for efficient biomass pellet production. With high production capacity and robust design, our machines deliver exceptional performance. Invest in our pellet machines and enhance your production efficiency today.

Read also Briquette Machine.

Please visit our official Facebook Page for updates from us.

For more details about our products and services please contact us at +91 96876 15656, +91 99133 77377, +91 87584 77377 or write us at info@ronakeng.com.