- Have any questions?

- +91 87584 77377

- +91 96876 15656

- info@ronakeng.com

Types of Briquetting Machines

Woodchipper

November 17, 2022

Biomass Briquettes

November 22, 2022Types of Briquetting Machines

Briquetting Machines are used to transform the waste powder into a standard shape block, which can help with dealing with the circumstances of those powders, simplify them for transportation, and storing, and be more useful for extra usage.

Screw type

The screw-type briquetting machine uses the drill to press the unrefined components, with different materials, which might be furnished regardless of the warming system to yield briquettes. The warming framework is a well-conceived plan for those briquettes that oversee materials that contain lignin, which can be tracked down on biomass. So the warming structure is normally used for biomass briquetting. Various materials like coal, charcoal, thus folios are expected while Briquette Machine with a screw-type briquette machine.

Roller type

The Roller Press Briquetting Machine works with two close-turning rollers at a comparable speed yet with an opposite course. The two rollers, with a comparative width and distance across, have openings on a shallow level. Right, when they move, comparable two openings on the unmistakable roller will fit at the intermingling of the midline and the briquette will be pressed there.

Pressure-driven sort

The water-powered sort works with a water-driven siphon station which supplies an outstandingly gigantic squeezing factor. Because of its high squeezing factor, basically, all of the materials can be briquette with this system. The briquette working communication is in a chamber where materials are dealt with, their materials are briquetting under uncommonly high strain. It causes their flexibility and makes them limit consistently out and out.

Cylinder type

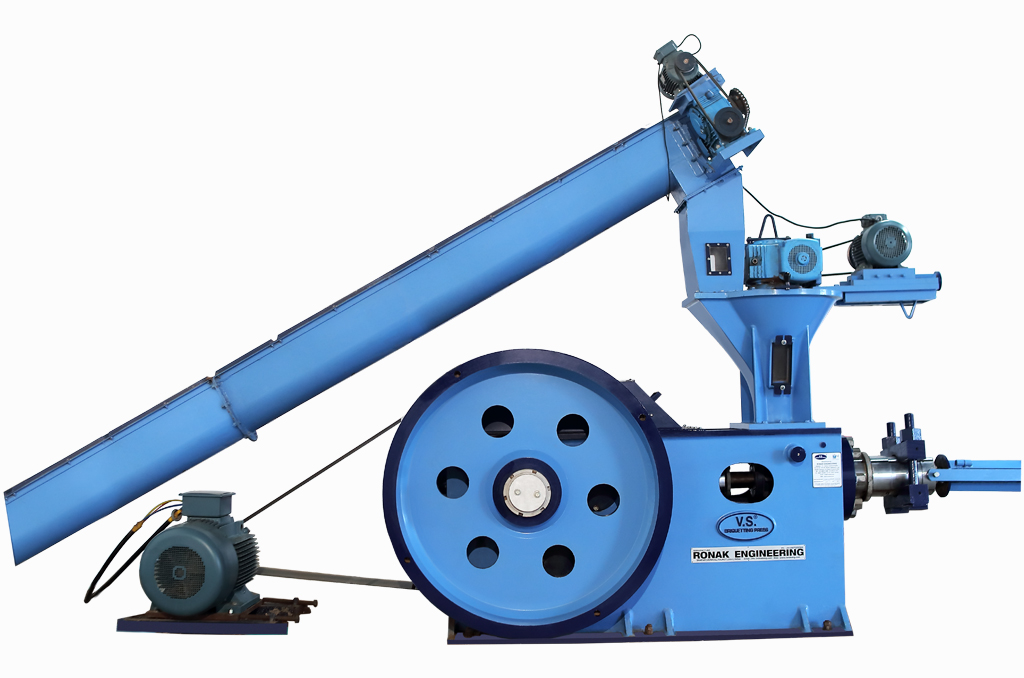

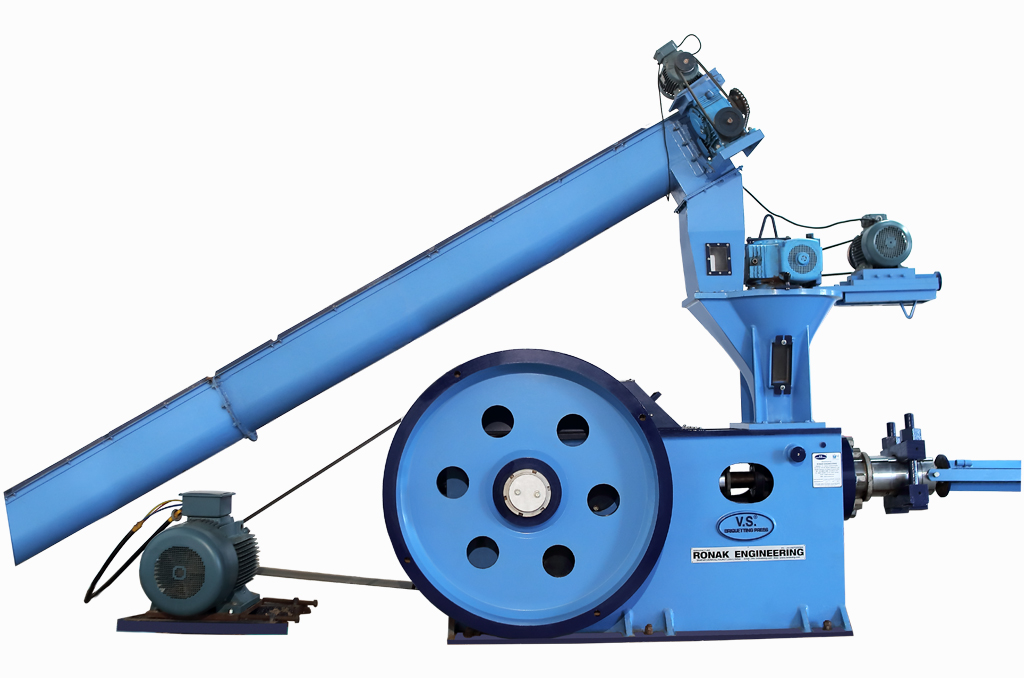

The Cylinder Type Briquetting Machine uses the rotating power of the mechanical contraption or the push of the water-controlled chamber to answer the cylinder, and the cylinder drives the crush to respond in the embellishment sleeve to make an ability to devastate to frame the material to briquette.

A significant squeezing variable will be delivered as the improvement of the flywheel and punch of the briquette again and again in a short period of time. It raises the temperature of the unrefined material. As the unrefined material moves, it fractionates inside, and another kind of warmth – grinding warmth makes. With the movement of these two kinds of warmth, the material raises its temperature to a Briquetting Machine critical level and disintegrates the lignin. Particle materials then, at that point, integrate and become sufficient.

Read Blog: Woodchipper