Gujarat has steadily become one of India’s strongest regions for biomass fuel production. From agricultural belts to industrial zones, more businesses here are adopting a briquetting machine to convert waste into a low-cost, clean-burning fuel. The state offers everything needed for this sector to grow—raw material, industry demand, transport networks, and experienced manufacturers. This makes Gujarat a natural leader in biomass briquetting across the country.

Why is Gujarat ahead in biomass briquetting?

Gujarat didn’t become a briquetting hotspot overnight. The state has three advantages that naturally support the growth of the sector:

Large availability of agricultural residue

Strong industrial clusters that need heating fuel

A well-connected logistics network

Because of these factors, setting up a biomass briquetting machine becomes easier and more profitable here. Industries quickly understood that briquettes burn cleanly, reduce boiler maintenance, and offer a more stable fuel cost compared to coal and wood. This shift helped Gujarat move far ahead of other states.

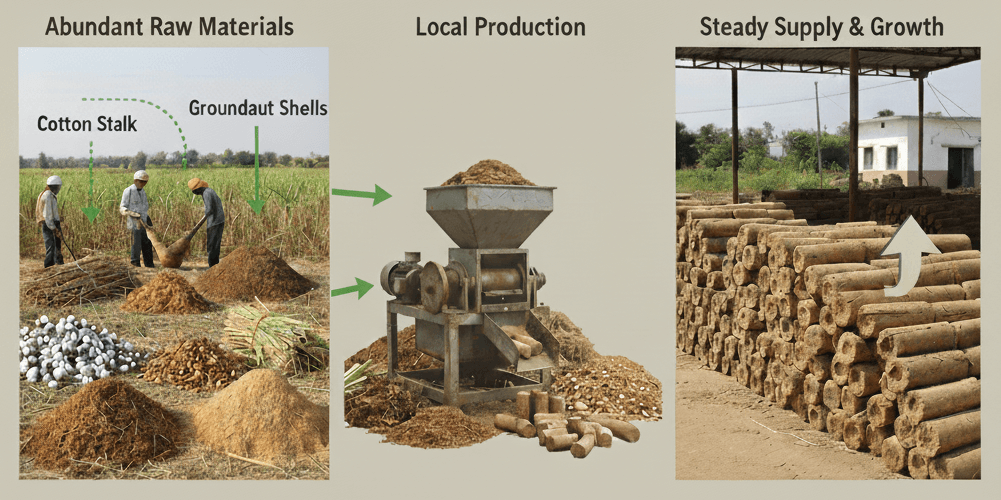

How does agriculture support briquette production?

Agriculture is the backbone of biomass fuel in Gujarat. Every year, huge volumes of crop residue are produced in districts like Junagadh, Amreli, Rajkot, Bhavnagar, and Banaskantha. Instead of burning or throwing it away, this waste is now used to make briquettes.

Common raw materials include:

Cotton stalk

Groundnut shells

Castor husk

Sugarcane bagasse

Rice husk

Sawdust and wood chips

Since the raw materials are available locally year-round, briquette production remains steady. This reliability is one of the main reasons the number of biomass briquette manufacturers in Gujarat keeps increasing.

Why do Gujarat’s industries prefer biomass fuel?

The state has a strong industrial base—textile mills, ceramic factories, food units, chemical plants, and engineering companies. Most of these industries run boilers, dryers, and furnaces every day, which creates a high demand for affordable fuel.

Briquettes quickly became popular because they:

Generate high heat

Produce less ash

Give a steady burn

Reduce chimney cleaning

Lower pollution levels

Industries in Morbi, Vapi, Rajkot, Surat, and Ahmedabad have already switched large portions of their fuel requirements to biomass briquettes.

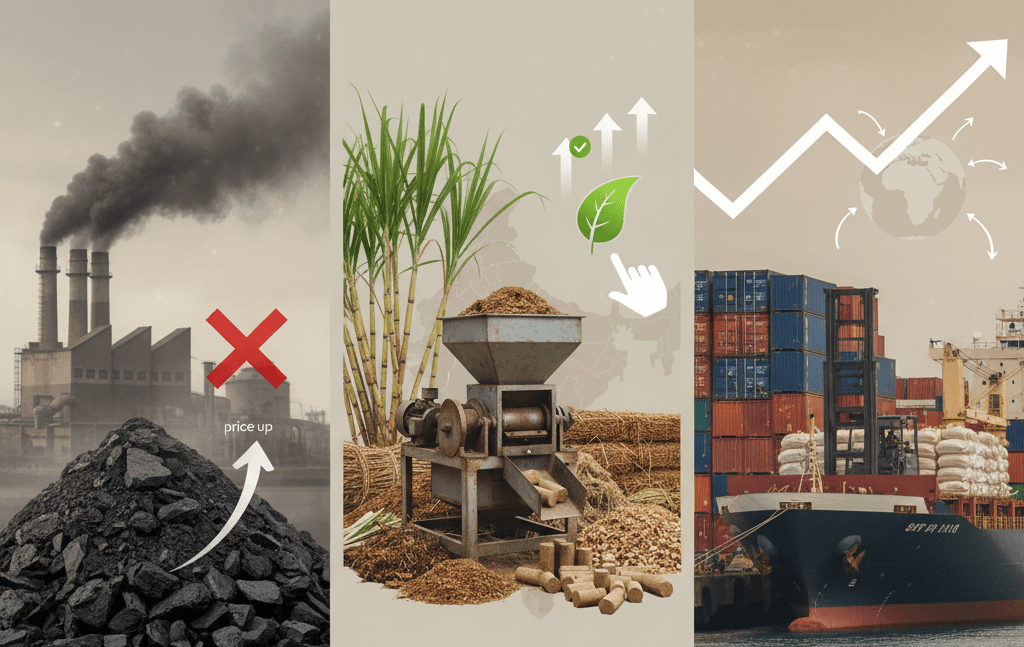

How does briquetting reduce energy costs?

Fuel cost is one of the biggest expenses for factories. Switching to briquettes often brings a noticeable reduction in operating cost. The main reasons include:

Briquettes cost less per ton than coal

No extra expense for chemical treatment or washing

Less wear and tear on boilers

Lower storage and handling costs

Easy transportation from local suppliers

Because fuel prices remain stable throughout the year, companies can plan their production more accurately. This cost advantage makes the briquetting machine a practical investment for many businesses in Gujarat.

Why are entrepreneurs choosing briquetting machines in Gujarat?

Entrepreneurs in Gujarat have always been quick to adopt new manufacturing opportunities. Briquetting has become attractive for small and medium units because:

The raw material is easily available

Machinery options are available in different capacities

Skilled workers are accessible

Local demand is high

Maintenance is simple

Even first-time business owners find it easy to start, as the technology does not require specialized training. The briquetting press also runs efficiently with basic supervision, which helps keep operational costs low.

How strong is the demand for briquettes in the state?

The market for biomass fuel is growing rapidly, thanks to:

Rising coal prices

Industry pressure to reduce emissions

Better awareness of renewable fuels

Supportive government policies

Expanding export opportunities

Factories across Gujarat look for fuel that is clean, dependable, and economical. Briquettes fit all three needs, which is why the demand continues to rise every year.

Why is Rajkot known for briquetting machine manufacturing?

Rajkot has earned a strong reputation for engineering and machinery production. Over the years, it has become home to several well-known manufacturers in this field. Companies here have invested in better design, durable materials, and long-lasting components.

The result is a trusted ecosystem where buyers can find reliable suppliers, quick spare parts, and good after-sales service. This is why many people specifically search for a briquetting machine in Rajkot when comparing machines.

Contribution of Ronak Engineering

One of the companies shaping this industry is Ronak Engineering. Based in Rajkot, they manufacture machines that work with different agricultural and industrial waste materials. Their focus on durability, simple operation, and consistent output has helped many businesses switch to biomass fuel confidently.

Ronak Engineering also supports customers with guidance on raw material handling, unit setup, and long-term maintenance—making the transition smooth for new entrepreneurs.

Conclusion

Gujarat’s combination of strong agriculture, a large industrial base, and solid infrastructure has made it the leading hub for biomass briquetting in India. Whether you are planning a new project or upgrading your existing unit, this is one of the best places to invest in sustainable fuel solutions.

If you want dependable machinery and long-term support, Ronak Engineering can help you choose the right briquetting machine for your needs.

Reach out today and move one step closer to a cleaner, smarter, and more cost-efficient fuel system.