- Have any questions?

- +91 87584 77377

- +91 96876 15656

- info@ronakeng.com

Making of Charcoal Briquettes

Where Are Briquettes Used?

December 24, 2022

What Are The Advantages Of Burning Sawdust/Wood Briquettes?

December 29, 2022Making of Charcoal Briquettes

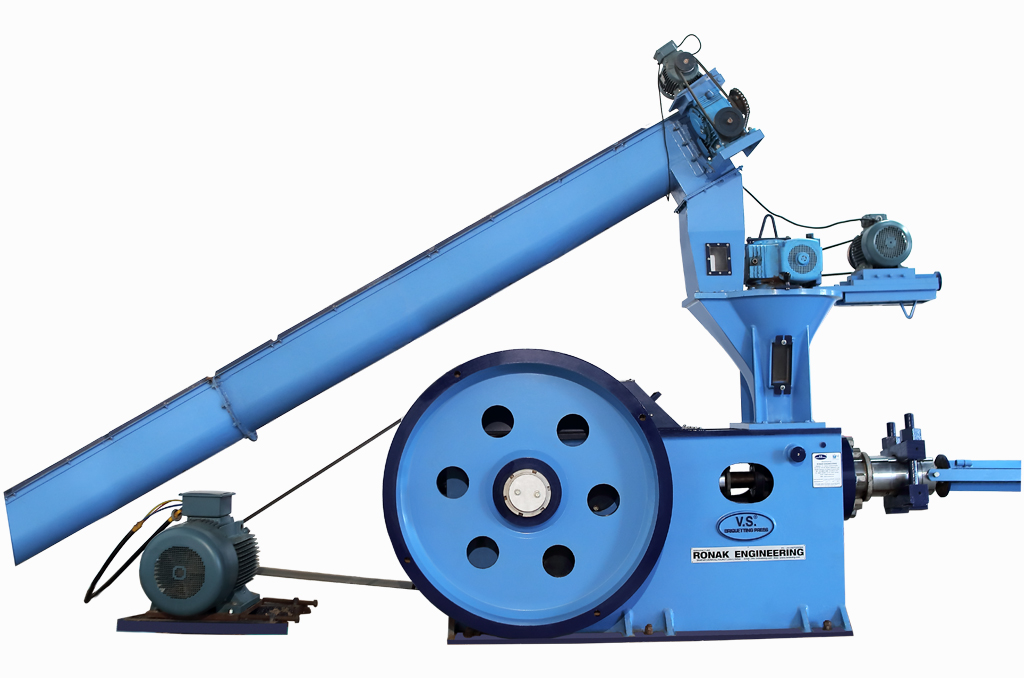

Steps to make charcoal briquettes are a solicitation that individuals by and large consideration about. The technique related to creating charcoal briquettes can be separated into five stages:

Step 1: Carbonization

As a matter of some importance, fire the typical substances in a rotational broiler. During the one-week start process, the temperature should be kept up at roughly 840-950 °F. After the fruition of the beginning, close the air channel, and following one to two hours of exhaust, close the exhaust opening. Following a fourteen-day cooling period, void the radiator and pound the carbonized wood.

Step 2: Crushing

Utilize a hammer smasher or roller smasher to pound the carbonized wood. However various kinds of wood, for example, bark, dry wood chips, wet wood, etc ought to be squashed into various sizes, and surroundings, they can be squashed into bits of charcoal up to 5mm under to make top-notch charcoal briquettes.

Step 3: Drying

Then, a drying association is required. Expecting the water content beats the observational furthest end, the temperature will increase and the volume will connect out of nowhere, which effectively goals an effect. Assuming the clamminess content is extravagantly low, it will be attempting to outline. Utilize a dryer to decrease its soaked substance to the level expected for briquette improvement by about half.

Step 4: Briquetting

Briquetting is a basic stage in charcoal trim. After the ordinary substances enter the ball press, they will be given three sorts of capacities, expressly the exceptionally basic role of the briquette machine, the deterioration force, and the centripetal power of the wall. Because of the wetness, glues, temperature, and sort of rollers of the briquetting machine, charcoal briquettes can remain mindful of their shape when they tumble from the lower part of the machine.

Step 5: Drying

Feed the charcoal briquettes into the dryer for around three to four hours to warm them to 275 °F and decline the drenched state to around 5%. After creation, pack the charcoal briquettes right away or store them in storage facilities. Following the above pushes, charcoal briquettes will be conveyed at a creation speed of 2200-20,000 pounds consistently.

Read more about Where Are Briquettes Used?