- Have any questions?

- +91 87584 77377

- +91 96876 15656

- info@ronakeng.com

Process of Making Charcoal Briquettes

How To Make Charcoal Briquettes?

July 5, 2022

Advantages of Wood Briquettes

July 9, 2022Process of Making Charcoal Briquettes

Step-by-step instructions to create charcoal briquettes are an inquiry that individuals for the most part care about. The method involved in creating charcoal briquettes can be partitioned into five stages:

Step 1: Carbonization

First and foremost, fire the natural substances in a rotational oven. During the one-week ignition process, the temperature should be kept up at roughly 840-950 °F. After the finish of ignition, close the air bay, and following one to two hours of exhaust, close the exhaust opening. Following a fourteen-day cooling period, void the furnace and pound the carbonized wood.

Step 2: Crushing

Utilize a mallet smasher or roller smasher to pound the carbonized wood. Albeit various kinds of wood, for example, bark, dry wood chips, wet wood, etc ought to be squashed to various sizes, by and large, they can be squashed into bits of charcoal to 5mm underneath to make top-notch charcoal briquettes.

Step 3: Drying

Then, at that point, a drying interaction is required. Assuming the water content surpasses the observational furthest cutoff, the temperature will climb and the volume will extend out of nowhere, which is not difficult to cause a blast. On the off chance that the dampness content is excessively low, it will be challenging to form. Utilize a dryer to decrease its dampness content to the level expected for briquette development by about half.

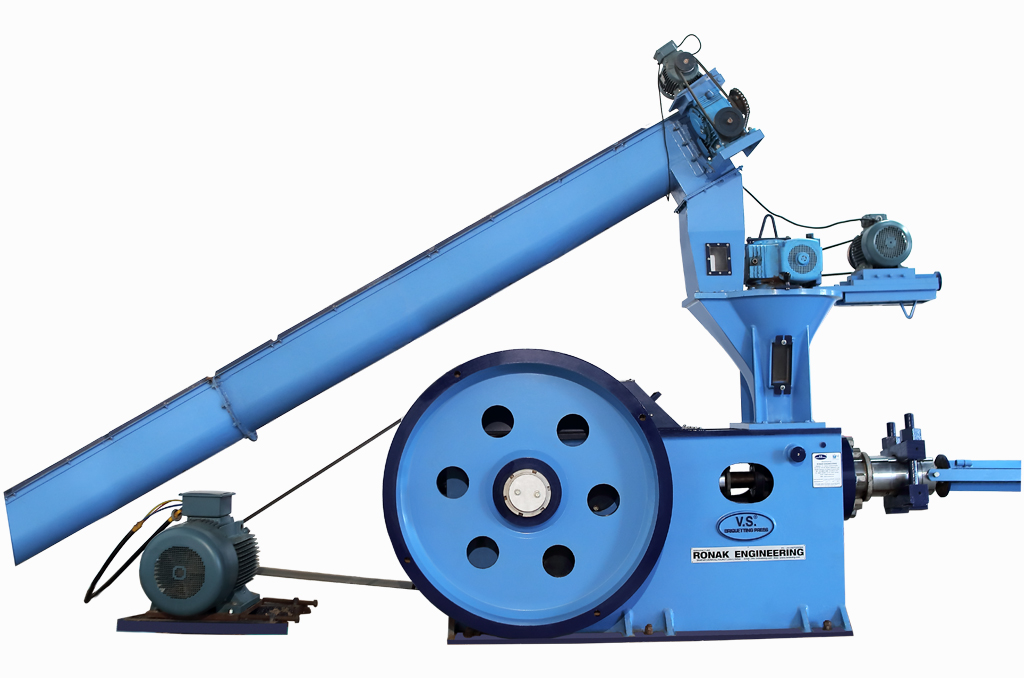

Step 4: Briquetting

Briquetting is a key stage in charcoal trim. After the natural substances enter the ball press, they will be exposed to three sorts of powers, specifically the super main thrust of the briquette machine, the erosion force, and the centripetal power of the wall. Because of dampness, glues, temperature, and strain of the rollers of the briquetting machine, the charcoal briquettes can keep up with their shape when they tumble from the lower part of the machine.

Step 5: Drying

Feed the charcoal briquettes into the dryer for around three to four hours to warm them to 275 °F and decrease the dampness to around 5%. After creation, pack the charcoal briquettes right away or store them in storehouses. Following the above advances, charcoal briquettes will be delivered at a creation pace of 2200-20,000 pounds each hour.

Read more about How To Make Charcoal Briquettes?