- Have any questions?

- +91 87584 77377

- +91 96876 15656

- info@ronakeng.com

Steps to Make Charcoal Briquettes

Which is Better Briquettes or Charcoal?

August 27, 2022

Biomass Briquettes

September 1, 2022Steps to Make Charcoal Briquettes

Step-by-step guidelines to make charcoal briquettes are a request that people generally care about. The strategy associated with making charcoal briquettes can be divided into five phases:

Step 1: Carbonization

As a matter of some importance, fire the normal substances in a rotational broiler. During the one-week start process, the temperature ought to be kept up at approximately 840-950 °F. After the completion of the start, close the air inlet, and following one to two hours of exhaust, close the exhaust opening. Following a fourteen-day cooling period, void the heater and pound the carbonized wood.

Step 2: Crushing

Use a hammer smasher or roller smasher to pound the carbonized wood. Yet different sorts of wood, for instance, bark, dry wood chips, wet wood, and so on should be crushed to different sizes, all around, they can be crushed into pieces of charcoal to 5mm under to make first-class charcoal briquettes.

Step 3: Drying

Then, a drying connection is required. Expecting the water content outperforms the observational uttermost end, the temperature will rise and the volume will reach out all of a sudden, which is easy to cause an impact. If the moistness content is exorbitantly low, it will be trying to frame. Use a dryer to diminish its sodden content to the level expected for briquette improvement by about half.

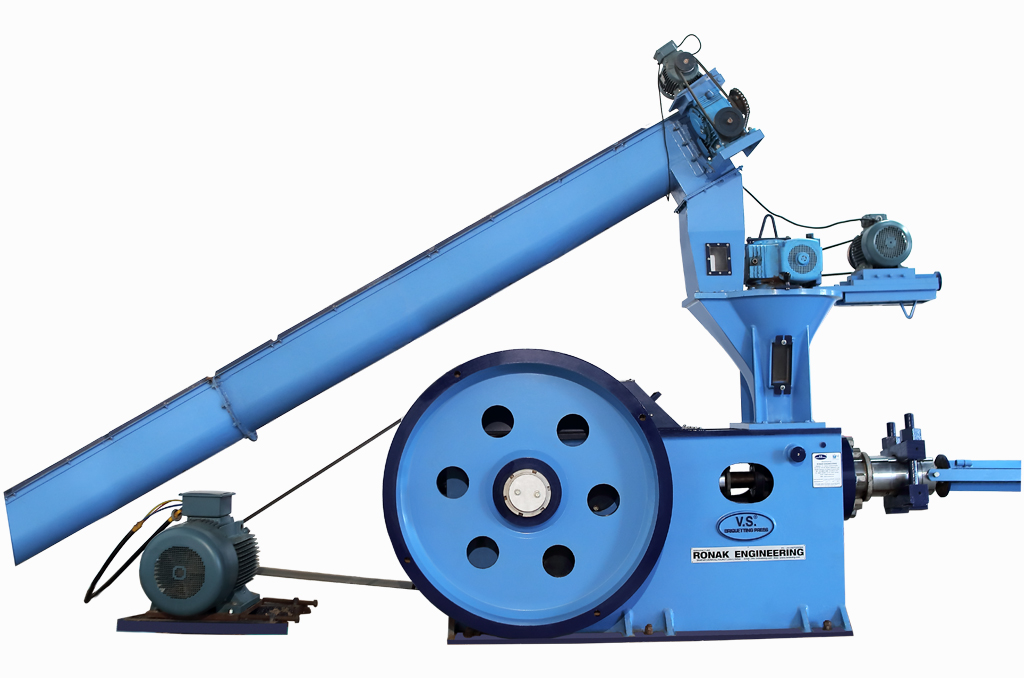

Step 4: Briquetting

Briquetting is a critical stage in charcoal trim. After the normal substances enter the ball press, they will be presented with three kinds of abilities, explicitly the very primary purpose of the briquette machine, the disintegration force, and the centripetal force of the wall. Due to the sogginess, pastes, temperature, and kind of rollers of the briquetting machine, charcoal briquettes can stay aware of their shape when they tumble from the lower part of the machine.

Step 5: Drying

Feed the charcoal briquettes into the dryer for around three to four hours to warm them to 275 °F and decline the soddenness to around 5%. After creation, pack the charcoal briquettes immediately or store them in storage facilities. Following the above propels, charcoal briquettes will be conveyed at a creation speed of 2200-20,000 pounds every hour.

Read more about Which is Better Briquettes or Charcoal?